Unitronics PLC controllers

Programmable controllers, thanks to their versatility, compactness, modularity and easy reprogramming, are part of the control systems in virtually all branches of industry. The task of the PLC is to execute a program that implements the control algorithm. The arguments of its functions are the states of PLC inputs, and the result of their processing - signals on the controller output. The device also communicates with other system components and carries out self-diagnostic tasks. Unitronics PLC can communicate by many industrial protocols like Modbus RTU, Modbus TCP, CANopen. It is possible to communicate by serial ASCII. We can develope new protocols in this way or communicate by some dedicated protocols. It is very useful with printers, gps modules or devices communicated by AT commands.

I/O

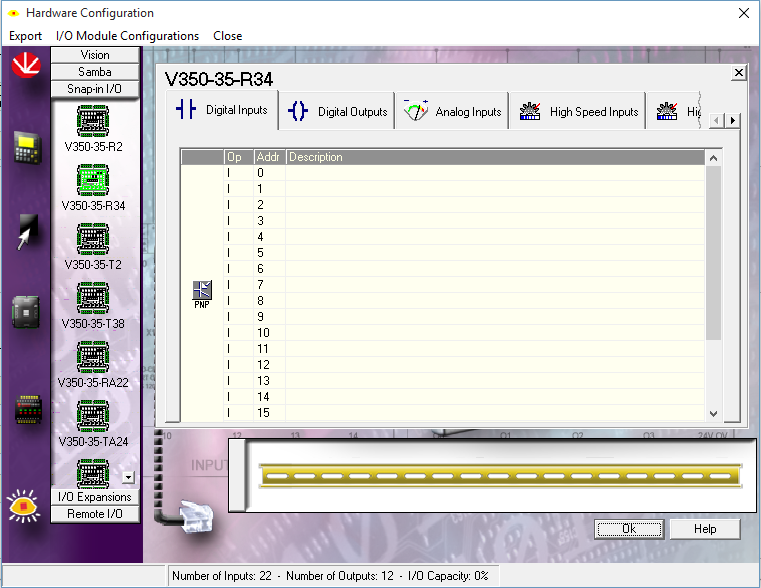

The purpose of analogue PLC inputs is to convert continuous signals into digital ones, whose values can be further stored in memory and processed by the processor. The first ones are voltage signals, usually with values of -10 V ... +10 V, 0 ... + 10 V or 1 ... + 5 V or current, usually in the range of 0 ... 20 mA or 4 .. .20 mA. They reflect changes in physical quantities - for example temperature, pressure, level or flow, measured by sensors monitoring the course of the controlled process. Analog voltage inputs are systems with high input impedance, the order of MΩ. In the case of currents, the value of this parameter does not exceed 500Ω. They can be Differential or Single-Ended - in the first one the difference in voltages between two inputs is processed, while in the second one the reference voltage is the common ground for all inputs. The advantage of differential inputs is greater resistance to external disturbances. However, single-ended ones are characterized by a higher packing density of inputs in a single module. However, the wires connecting them to the signal source should be shielded. It is worth remembering that if necessary, when the signal source is remote from the PLC, we can use distributed I / O modules. Unitronics PLC I/O list configuration is very intuitive and easy. Adding new modules is realised by drag and drop.

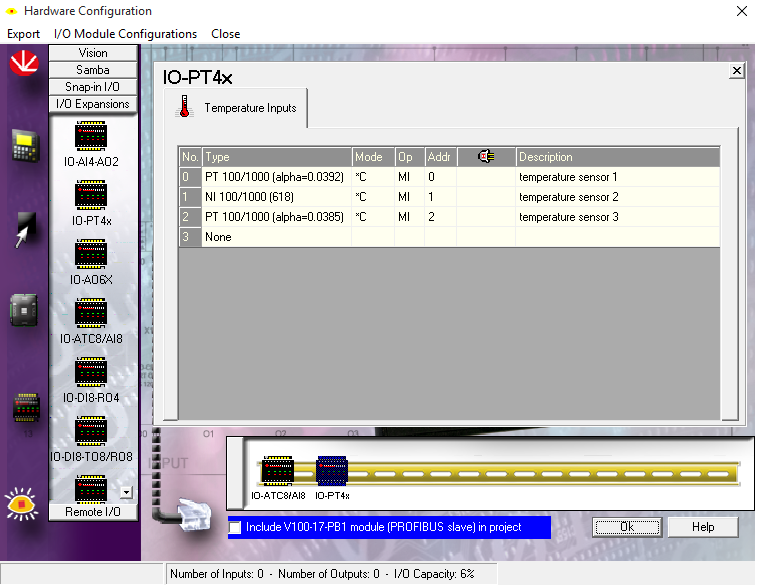

Temperature measurement

Temperature input modules cooperating with thermocouples are also popular. Like the usual analog ones, they first amplify the signal from the sensor and later convert it to a digital form. At the same time, however, they convert the voltage value into temperature in accordance with the characteristics of the type of thermocouple. In addition, they provide cold junction compensation (Cold Junction Compensation) that simulates keeping the temperature of the open end of the thermocouple at a constant temperature and compensating for signal loss on the lead resistance. Similar conversion to temperature, only changes in electrical resistance, are made by temperature input modules cooperating with resistive sensors.